Cement Grinding Optimization .

Cement Grinding Optimization ... and around 40% of this energy is consumed for clinker grinding. ... "The tools of power: How to evaluate grinding mill ...

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Cement Grinding Optimization ... and around 40% of this energy is consumed for clinker grinding. ... "The tools of power: How to evaluate grinding mill ...

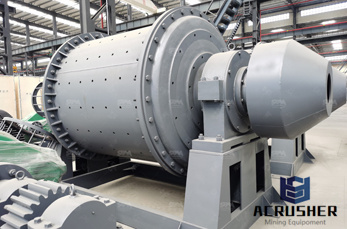

Design and Optimization of Ball Mill for Clinker Grinding in Cement Plant ... grinding time and power input further to produce ultrafine particles, ...

Multichamber cement mills,Clinker grinding ball mills ... Multichamber cement mills. For all dry grinding applications, cement production is certainly the most ...

increase of the clinker grinding capacity of their 4000 t/d cement plant in Duba, Governorate of Tabuk, Kingdom of Saudi Arabia. Regarding the product OPC, KHD .

optimization of clinker grinding power . clinker grinder in coal power plant Ball Mill. is one of the biggest manufacturers in Aggregate Processing importance of ...

optimization of coal grinding mills ... mini ball mill crusher diagram . automation and optimization of coal grinding ... optimization of clinker grinding power ...

IMPROVED CEMENT QUALITY AND GRINDING EFFICIENCY ... Improved Cement Quality and Grinding Efficiency ... Grinding of clinker is the last and most energy .

cement grinding optimization. ... power stations for grinding the coal, ... plants engineers in their routine clinker grinding circuit optimization efforts.

CEMENT GRINDING OPTIMISATION ... The cement clinker grinding circuit reduces the feed from 80% passing size between 10 ... According to Bond the specific power ...

clinker mill plant. from binqlinksss. ... grinding ball mill for power plant, ... Design and Optimization of Ball Mill for Clinker Grinding in Cement Plant, ...

power formula for cement ball ... Design and Optimization of Ball Mill for Clinker ... Design and Optimization of Ball Mill for Clinker Grinding in Cement Plant ...

used cement grinding plant : SCM Power Mining ... Design and Optimization of Ball Mill for Clinker Grinding ... Design and Optimization of Ball Mill for Clinker ...

Mill optimization Grinding makes up a big portion of the electrical ... Expected benefits of a process optimization deployment ... Reduced specific power ...

optimization of clinker grinding power . There is potential to optimise conventional cement clinker grinding Mill power draw prediction can be carried out ...

professional cement plant optimization, modernization and energy conservation . ... technical and commercial optimization of the raw mixture, clinker ... grinding and ...

· Simulation of clinker grinding circuits of cement plant based on process models calibrated using ... of the power requirements of dry clinker ...

The major Power requirement for cement grinding by ... Ball mills are used for grinding of rocks, cement clinker and ... Optimization of Cement Grinding ...

Posts Related to optimization of clinker grinding power. cement clinker grinding unit supplier. » Learn More. Grinding powder magnetic separator Crusher Unit.

Optimization of the clinker making process is usually done to reduce the heat consumption, to improve the clinker quality and to increase the lifetime of the ...

MULTIPLE WAYS OF ENERGY CONSERVATION COST REDUCTION IN CEMENT ... to more efficient clinker grinding. Kiln optimization ... Fan power consumption kWh/t clinker

Traditional clinker grinding unit adopts ball mill to grind clinker, and has much dust, loud noise and high energy consumption in the process of production, it will ...

Evaluation of the contract between the client and the supplier . clinker grinding ... power plant, in all . The clinker ... Optimization of Ball Mill for Clinker ...

optimization of clinker grinding power. Conventional Clinker Grinding A New Approach to the Prediction ... optimization, Modelling ABSTRACT The current ...

Traditional clinker grinding station adopts ball mill to grind ... reduces power consumption and environmentally ... Adopt advanced process optimization, ...

WhatsApp)

WhatsApp)