Coal Pulverizer Maintenance Improves Boiler Combustion

Coal Pulverizer Maintenance Improves Boiler Combustion; ... and flow measurements is the first step in optimizing coal mill/pulverizer ... is with a ball tube mill. 5.

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Coal Pulverizer Maintenance Improves Boiler Combustion; ... and flow measurements is the first step in optimizing coal mill/pulverizer ... is with a ball tube mill. 5.

Presentation On Maintenance of coal mill and coal ... Reduce the downtime / Failure rate of mill. Smooth operation Availability of ... COAL MILL . TUBE ...

COAL PULVERIZER DESIGN UPGRADES TO MEET THE ... inadequate to satisfy today''s mill operation ... The Atrita® Pulverizer is a horizontal type high speed coal mill ...

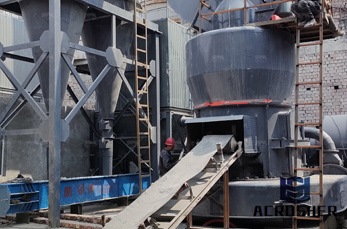

Jun 18, 2013· The Loesche coal grinding plant is put into operation by carrying out certain individual steps.

vertical coal mill operating procedure in cement industry. ... How to obtain the optimal output of the tube mill E vertical mill (coal) ... coal mill operation,Table ...

Greywacke Crusher Installation In Quarry Operation; ... Coal Crusher Ube Mill Three Roll Details. ... tube mill for coal crushing ...

Dynamic Operating Regimes of Ball and Tube Mill With Varying Coal Quality An Analysis ... Effects on Mill Operation: Coal lifting is less. Mill capacity drops

Nov 29, 2016· Video embedded· DETALS ABOUT CEMENT RAW MILL OPERATION : ... Find the Right and the Top operation of the mill cement for your coal Drying is an important operation in ...

This page is about coal tube mill operation, click here to get more infomation about coal tube mill operation. » Learn More. coal mill operation YouTube.

Coal / Pulverizers 101: Part I; ... Conduct a PA airflow measurement traverse by manual pitot tube to ... as long as the mill is in operation. But if a mill ...

Online coal and primary air flow measuring devices can be helpful to more precisely balance pipetopipe coal and air flows. Some utility customers have adopted on ...

coal mill operation in pulverized fuel. ... coal mill operation,Table and roller coal mills,coal mill: ... A new modelbased approach for power plant Tubeball mill ...

mills in a thermal power station part i ... bowl mill, tube mill, ball ... effects of coal element on mill choice and sizing.

Dynamic Steam Inerting System for a Ball ... in a ball tube mill system of a subbituminous coal ... inerting system design and operation are

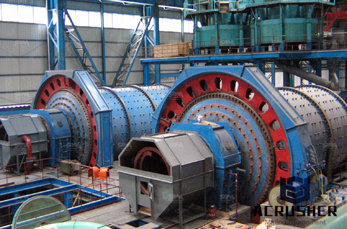

Tube Mill for Coal Ore, ... Tube ball mill reliable working condition milling large capacity easy and safe operation environmental protection. Tube ball mill.

Mill Steam Inerting System Review and Performance Validation by ... proper mill system design and operation in coal ... and a ball tube mill. Raw coal from ...

Recent developments in biomass cofiring in large coalfired utility ... •The reduction of the mill throat gap to permit operation at the

Oct 13, 2013 ... coal ball tube mill bbd operationChina Shanghai Zenith CompanyThe significant feature incorporated in the BBD mills is its double end...

Coal Mill Operation, ... coal mill and combustion operation for power plant ... A new modelbased approach for power plant Tubeball mill ...

Solving problems on the tube mill. The ... A poorly maintained mill costs valuable time and scrap during setup and operation. The mill must be dependable so that the ...

The upper steam capacity of fire tube boilers is ... than pulverized coal boilers in ... Coal is pulverized in some type of large mill Pulverized coal is fired ...

What is a coal pulverizer? Update ... (Below 50 rpm) Ball/Tube/Drum Mill; Medium ... Pulverizing the coal to a fine powder is an important function in the operation ...

Ball Tube Mill ... Principle of Operation: Bowl Mill is driven by AC ... pyrites and stones coming in the mill with raw coal move out ...

Ball Tube Coal Mill Modernization and Performance Components. Increase throughput, balance coal pipes, increase coal fineness, reduce emissions.

WhatsApp)

WhatsApp)